- Introduction to automatic batching machine and fully automatic batching machine equipment

- The powder metering system tells you about the introduction of the mixing and drying machine

- 1000kg vacuum feeding machine

- Fully automatic small material batching system

- Research on Innovation of Automatic Weighing Machine Technology

- Design and operation of automatic batching system using PLC, industrial computer and frequency converter

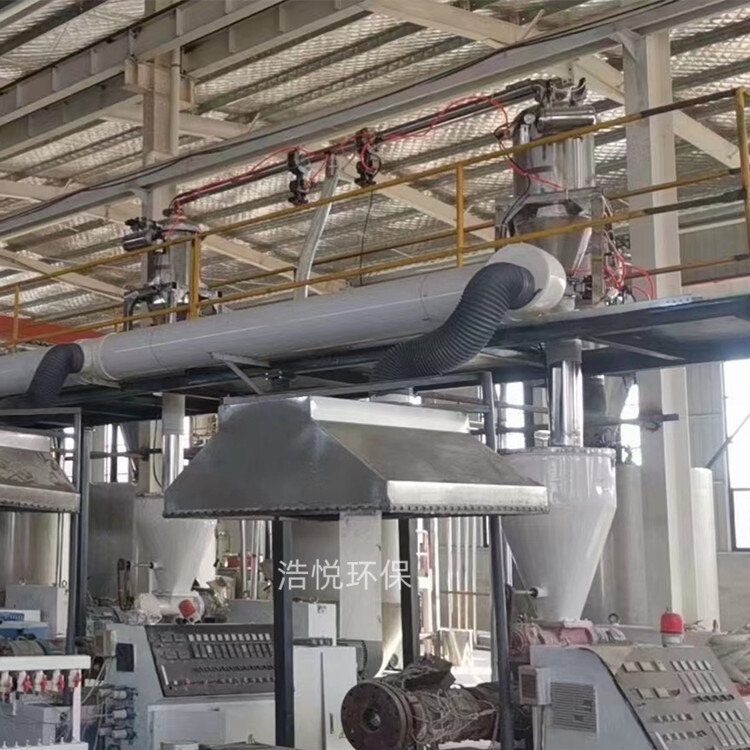

Vacuum feeding machine manufacturer

- Category:Automatic metering and conveying equipment

- Hits:183次

- Release Date:2025-06-27

- Share:

- Inquiry

- Details

1、 Definition and core value of vacuum feeding machine

A vacuum feeder is a material conveying equipment designed based on the principle of vacuum negative pressure. It achieves automated conveying of materials such as powders, particles, and blocks by creating a pressure difference in the airflow inside a closed pipeline. In industries such as chemical, food, pharmaceutical, rubber and plastic, and new energy, it has replaced traditional manual feeding or mechanical conveying methods and become a key equipment for improving production automation levels. Its core value lies in eliminating material pollution and dust leakage through closed conveying, reducing labor costs through automated control, and ensuring production process stability through precise flow control. According to industry data statistics, compared to traditional conveying methods, vacuum feeders can increase material conveying efficiency by 30% -50% and reduce dust emissions by more than 90%.

2、 Working principle and analysis of core components

(1) Negative pressure formation and transport mechanism

The working principle of the vacuum feeder can be disassembled into four stages: "negative pressure generation - material picking - pipeline transportation - unloading control":

Negative pressure generation: After the vacuum pump (such as rotary vane, water ring, Roots) is started, the air in the conveying pipeline and hopper is discharged through the suction port, forming a negative pressure environment with a vacuum degree of -20kPa to -80kPa (the specific value is adjusted according to the material characteristics).

Material picking: Under negative pressure, the external atmospheric pressure presses the material in the storage bin into the suction port, and enters the conveying pipeline through the suction hose. At this time, the material and the airflow form a gas-solid two-phase flow.

Pipeline transportation: Materials move along the pipeline driven by airflow, and the airflow velocity inside the pipeline is usually controlled at 15-30m/s (high value for granular materials and low value for powder materials) to avoid material deposition or pipeline wear.

Unloading control: When the material reaches the feeding hopper of the feeder, gas-solid separation is carried out through a filter element (precision 5-10 μ m). Clean air is discharged through a vacuum pump, and the material falls into subsequent equipment through gravity or pneumatic butterfly valves.

(2) Detailed explanation of key structural components

Component Name Function Common Types and Materials

Vacuum pumps provide negative pressure power source rotary blades (suitable for dry environments), water ring type (moisture resistant), Roots type (high flow rate)

Construction of material conveying channels for conveying pipelines: stainless steel 304/316L (food and pharmaceutical grade), wear-resistant PVC (chemical grade)

The hopper and filter element achieve gas-solid separation and material temporary storage. The filter element material is polytetrafluoroethylene, polyester fiber, and the filtration accuracy is selected according to the particle size of the material

Control system adjusts vacuum degree, controls start stop and fault alarm PLC control system (supports Modbus protocol), touch screen human-machine interface

The suction component includes a suction port and a suction hose, which realize material picking. The hose material is food grade silicone and anti-static PVC

The unloading device controls the rhythm of material discharge, commonly using pneumatic butterfly valves and flap valves made of stainless steel with sealing rubber rings to prevent leakage

3、 Classification method and typical model characteristics

(1) Classified by power source

Electric vacuum pump type:

Features: Driven by a motor, the vacuum pump has stable vacuum degree and is suitable for continuous production scenarios

Typical model: rotary vane vacuum feeder (vacuum degree -40 to -60kPa)

Application scenarios: Plastic granulation, transportation of positive and negative electrode materials for lithium batteries

Pneumatic vacuum pump type:

Features: Using compressed air to drive the Venturi tube to generate negative pressure, with good explosion-proof performance without a motor

Typical model: Pneumatic vacuum feeder (vacuum degree -20 to -40kPa)

Application scenarios: Flammable and explosive materials (such as magnesium powder, pesticides), explosion-proof workshops

(2) Classified by transportation method

Dilute phase transport type:

Features: Low gas-solid ratio (1:5-1:10), high airflow velocity, suitable for granular materials (particle size>0.1mm)

Advantages: Long conveying distance (up to 50 meters), flexible pipeline layout

Case: Corn granule conveying in feed factory

Dense phase transport type:

Features: High gas-solid ratio (1:20-1:50), low airflow velocity, suitable for powder materials (particle size<0.1mm)

Advantages: Low material damage rate, energy savings of 15% -20%

Case: Pharmaceutical factory raw material powder transportation

(3) Specialized models according to application scenarios

Food grade vacuum feeding machine: made of all stainless steel 316L material, mirror polished (roughness Ra ≤ 0.8 μ m), in compliance with FDA certification

Explosion proof vacuum feeder: motor, control box explosion-proof grade Ex d IIBT4, anti-static hose grounding design

High temperature vacuum feeder: equipped with high-temperature resistant seals (temperature resistance ≤ 200 ℃), suitable for asphalt and fiberglass materials

4、 Technological advantages and industry application scenarios

(1) Five core technological advantages

Clean transportation: Fully enclosed pipeline design to avoid material contact with the outside world and meet GMP standards (such as in the pharmaceutical industry)

Energy saving and efficient: Compared to bucket elevators, energy consumption is reduced by 30% (taking the transportation of 10 tons/hour of material as an example, the power difference is about 5kW)

Flexible layout: Pipelines can be arranged horizontally, vertically, and curved to adapt to complex workshop environments (such as multi-level factory buildings for three-dimensional transportation)

Intelligent control: supports integration with MES system, real-time monitoring of parameters such as conveying volume and vacuum degree, and automatic warning of material blockage faults

Low maintenance cost: no mechanical transmission components (such as belts and chains), only filter elements and seals are vulnerable parts, replacement cycle ≥ 6 months

(2) Typical Industry Application Cases

1. Food industry: Chocolate bean vacuum feeding system

Material characteristics: particle size 5-10mm, moisture content<1%, no breakage required

Solution configuration: dilute phase conveying type, pneumatic vacuum pump (explosion-proof), stainless steel 304 pipeline (inner wall polished)

Technical parameters: conveying capacity of 8 tons/hour, conveying distance of 20 meters horizontally and 15 meters vertically, crushing rate<0.5%

2. Pharmaceutical industry: API powder vacuum feeding line

Material characteristics: particle size 10-50 μ m, strong moisture absorption, requiring a sterile environment

Solution configuration: dense phase conveying type, electric rotary vane vacuum pump, 316L stainless steel pipeline (passivation treatment), online cleaning (CIP) system

Technical parameters: Vacuum degree -60kPa, conveying capacity of 2 tons/hour, dust leakage rate<1mg/m ³

3. New energy industry: transportation of positive electrode materials for lithium batteries

Material characteristics: Lithium iron phosphate powder (particle size 2-5 μ m), strong conductivity, anti-static required

Solution configuration: Explosion proof vacuum feeder, anti-static PVC hose (surface resistance<10 ⁹ Ω), grounding resistance<4 Ω

Technical parameters: conveying capacity of 5 tons/hour, conveying distance of 30 meters, electrostatic voltage<50V

5、 Selection points and maintenance guidelines

(1) Six step selection method

Material characteristic analysis:

Physical properties: particle size, bulk density, flowability (angle of repose), hygroscopicity

Chemical properties: flammable, explosive, corrosive, toxic

Case: Titanium dioxide powder (resting angle>45 °, requiring dense phase transportation+anti sticking material design)

Determination of process parameters:

Conveying capacity (ton/hour), conveying distance (horizontal/vertical), feeding height

Example: To transport 15 tons/hour of flour, with a horizontal distance of 40 meters and a vertical distance of 8 meters, a high-power rotary vane vacuum pump needs to be selected

Environmental condition requirements:

Temperature (normal/high temperature), humidity (dry/humid), explosion-proof rating (such as Ex zone 1)

Pharmaceutical workshop needs to choose food grade stainless steel with online sterilization function

Automated docking requirements:

Is it necessary to link with PLC and DCS systems, interface protocol (Modbus/Profinet)

New energy production lines often require real-time data exchange with MES systems

Cost budget planning:

Initial investment: Pneumatic type (50000 to 100000)<Electric type (100000 to 300000)<Explosion proof type (300000 to 800000)

Operating cost: The energy consumption of water ring vacuum pumps (requiring water circulation) is higher than that of rotary vane pumps

After sales service considerations:

Does the supplier provide on-site debugging, training, and spare parts inventory cycle (such as filter cartridges and other vulnerable parts)

(2) Maintenance and upkeep procedures

Standard requirements for maintenance cycle project operation points

Daily filter cleaning with back blowing method to clean dust on the surface of the filter element, compressed air pressure 0.4-0.6MPa, filter element pressure difference<20kPa

Apply soapy water to the interface for weekly pipeline sealing inspection, and observe that there are no bubbles leaking (under vacuum)

Monthly vacuum pump oil level inspection: The oil level of the rotary vane vacuum pump should be maintained at 1/2-2/3 of the window. When the oil color turns black, the oil type should be changed. Model: Vacuum pump special oil N62

Simulate faults such as material blockage and insufficient vacuum degree during quarterly control system function testing, and check the alarm response time. The alarm response time should be ≤ 5 seconds

The annual overall performance calibration uses standard materials to test the conveying volume error, and the error range should be ≤± 3%. The conveying volume fluctuation should be ≤± 3%

6、 Industry development trends and technological innovation

Intelligent upgrade:

Equipped with an AI vision system, the material stacking status is recognized in real time through a camera, and the vacuum degree is automatically adjusted

Case: A listed company's vacuum feeding machine integrates machine learning algorithms, and the accuracy of material blockage warning reaches 98%

Energy saving and environmental protection technologies:

Variable frequency control of vacuum pump speed, dynamically adjusting power according to conveying volume (energy-saving 15% -25%)

Waste heat recovery system: using vacuum pump to heat materials (such as PVC granulation preheating)

Modular design:

Using quick detachable pipeline interfaces (such as clamp connections), the replacement time for components has been reduced from 4 hours to 30 minutes

Detachable hopper design to meet CIP/SIP online cleaning needs (pharmaceutical industry)

Application of new materials:

The filter element adopts nano coating technology, which improves adhesion resistance by 3 times and extends the cleaning cycle to 15 days

The inner wall of the pipeline is coated with PTFE to solve the problem of wall sticking caused by viscous materials such as hot melt adhesive

Unmanned integration:

Linkage with AGV car to achieve automatic positioning and feeding of vacuum feeding machine, suitable for flexible production lines

A certain automotive interior parts factory has reduced 60% of its workforce in the feeding position through this plan

As the core equipment of industrial automation conveying, the vacuum feeder is developing towards a more intelligent, efficient, and environmentally friendly direction. When selecting and using, it is necessary to combine industry characteristics and process requirements, fully leverage its advantages of sealing, precision, and energy saving, and provide solid equipment support for the digital transformation of enterprises. In practical applications, it is recommended to regularly track technical iterations and continuously improve production efficiency through equipment upgrades.