- Introduction to automatic batching machine and fully automatic batching machine equipment

- The powder metering system tells you about the introduction of the mixing and drying machine

- 1000kg vacuum feeding machine

- Fully automatic small material batching system

- Research on Innovation of Automatic Weighing Machine Technology

- Design and operation of automatic batching system using PLC, industrial computer and frequency converter

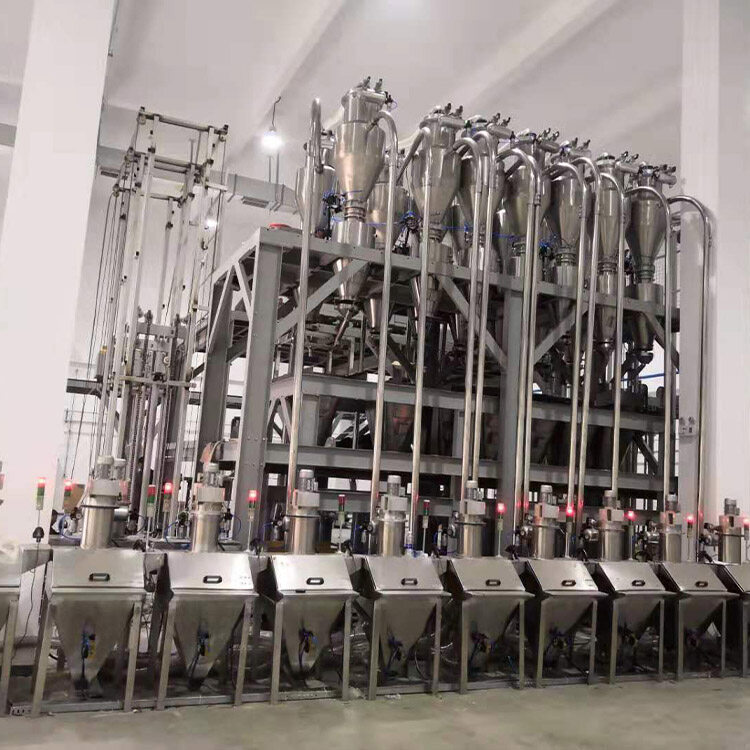

Vacuum conveyor

- Category:Automatic metering and conveying equipment

- Hits:170次

- Release Date:2025-06-23

- Share:

- Inquiry

- Details

1、 Working principle and core functions

The vacuum conveyor is based on the Bernoulli principle, which extracts air from a closed pipeline through a vacuum pump to create a negative pressure environment (typically ranging from -20kPa to -60kPa). Under atmospheric pressure, materials enter the pipeline from the feed inlet and are transported along the pipeline to the discharge outlet by the airflow. During the unloading process, the airflow is cut off by a vacuum breaking device or an air knife, allowing the material to fall into the receiving container by gravity. Its core functions include:

Efficient material conveying: It can achieve continuous conveying of various forms of materials such as powder, particle, and sheet, with a conveying distance of tens of meters, a horizontal conveying speed of up to 15m/s, and a vertical conveying height of over 10m, meeting the needs of different production line layouts.

Clean and environmentally friendly transportation: The fully enclosed pipeline design eliminates material contact with the outside world, preventing dust overflow and material leakage. The workshop dust concentration can be controlled below 1mg/m ³, which complies with environmental regulations and occupational health standards, especially suitable for industries with extremely high cleanliness requirements.

Flexible multi-point conveying: Through devices such as sorting valves, flexible configuration of "one machine, multiple lines" or "multiple machines, one line" can be achieved, conveying materials from multiple feeding points to single or multiple unloading points, adapting to complex production processes.

Safe and reliable operation: No direct contact between mechanical transmission components and materials, reducing equipment wear and material contamination risks; Equipped with overload protection, blockage alarm and other functions, it has high operational stability; For flammable and explosive materials, explosion-proof design can be adopted to ensure production safety.

2、 System composition and key structure

Vacuum generating device

Vacuum pump: commonly used rotary vane vacuum pump, Roots vacuum pump or multi-stage vacuum unit. Rotary vane vacuum pumps are suitable for low flow, medium low vacuum scenarios; Roots vacuum pump can provide high flow rate and high vacuum degree, suitable for long-distance and large conveying demand, with a vacuum degree of up to -90kPa or above.

Vacuum controller: monitors the vacuum level inside the pipeline, automatically adjusts the start and stop of the vacuum pump, maintains stable negative pressure, and avoids energy waste.

Transportation pipeline system

Pipeline material: Select stainless steel (304 or 316L), carbon steel, or food grade plastic according to industry requirements. Polishing treatment of stainless steel pipeline inner wall (roughness Ra ≤ 0.8 μ m), suitable for the food and pharmaceutical industries; Carbon steel pipelines are commonly used in cost sensitive fields such as chemical and building materials.

Pipeline layout: supports various combinations such as horizontal, vertical, and inclined, and uses large curvature radius elbows at turns to reduce material conveying resistance and wear.

Feeding and unloading unit

Feeding device: including suction nozzle, Venturi tube, etc. The suction nozzle is designed in the shape of a bell mouth, which facilitates the suction of materials; The Venturi tube utilizes high-speed airflow to generate negative pressure, enhancing material suction capacity, and is suitable for materials with poor fluidity.

Unloading device: common combination of cyclone separator and filter unloading valve. The cyclone separator separates the material from the airflow through centrifugal force, and the filter (such as polyester fiber filter bag, metal sintered filter element) further intercepts fine particles, with a filtration efficiency of 99.9%; Unloading valves (such as rotary valves and flap valves) control the discharge of materials to prevent air backflow.

control system

PLC+touch screen: Operators can set parameters such as conveying time, vacuum threshold, unloading cycle, etc; Real time display of device operating status, fault codes, and generation of operational data reports.

Intelligent linkage function: It is linked with upstream storage silos, downstream measuring equipment, or production hosts (such as injection molding machines and mixers) to automatically start and stop conveying based on material level signals, achieving unmanned operation.

3、 Technical features and advantages

Strong material adaptability: It can transport various materials such as flour, sugar powder, carbon black, plastic particles, pharmaceutical intermediates, etc. By adjusting the vacuum degree, pipeline diameter, and conveying speed, it can adapt to different material characteristics. For materials that are prone to agglomeration, air knives or vibration devices can be installed inside the pipeline to prevent blockage.

Low maintenance cost: no mechanical transmission components (such as belts and chains), reducing wear and maintenance frequency; The filter supports quick replacement and easy cleaning; Modular design facilitates equipment maintenance and upgrades.

Energy saving and efficient: Compared to positive pressure pneumatic conveying, vacuum conveyor reduces energy consumption by 15% -30%; Variable frequency control technology can adjust the power of the vacuum pump according to the actual conveying volume, further saving energy.

Compliant with industry standards: Equipment in the food and pharmaceutical industries meets GMP, FDA and other certification requirements, uses food grade materials and polishing treatment, and supports CIP (in-situ cleaning) function; Equipment in the chemical industry can meet special requirements such as explosion-proof (Ex) and anti-corrosion.

4、 Typical application scenarios

Food industry: used for conveying raw materials such as flour, milk powder, chocolate powder, etc., to avoid dust flying and foreign matter pollution; In candy and biscuit production lines, automated transportation of raw materials from storage warehouses to processing equipment is achieved to ensure food safety.

Pharmaceutical industry: Transporting pharmaceutical raw materials, intermediates, and finished particles, fully enclosed and clean design to prevent cross contamination; Cooperate with A-level clean areas to meet the requirements of sterile drug production.

Chemical industry: transporting powdered chemical raw materials such as carbon black, pigments, catalysts, etc. Explosion proof design suitable for flammable and explosive scenarios; In plastic modification production, precise transportation and proportioning of plastic particles and additives are achieved.

Electronics industry: used for conveying precision materials such as lithium battery positive and negative electrode materials, semiconductor silicon powder, etc. The anti-static design avoids material electrostatic adsorption and spark generation, ensuring production safety.

5、 Technological development trends

Intelligent upgrade: Introduce AI algorithms to optimize vacuum control and conveying paths, and achieve remote monitoring and fault warning of equipment through the Internet of Things; Real time monitoring of material flow and pipeline pressure using sensors, and automatic adjustment of operating parameters.

Energy saving and environmental protection: Develop efficient and energy-saving vacuum pumps (such as magnetic levitation vacuum pumps) to reduce energy consumption; Using renewable materials to manufacture pipelines and filters, reducing environmental pollution; Optimize system design to reduce noise to below 70dB.

Modularization and Customization: Launching standardized module components that support rapid assembly and functional expansion; Provide customized solutions based on customer specific needs (such as ultra clean and ultra-high pressure conveying) to enhance equipment versatility and adaptability.

Vacuum conveyors, with their unique technological advantages, have become the mainstream choice for modern industrial material transportation. With the continuous innovation of technology, it will continue to develop in intelligent, green, and efficient aspects, providing important support for the production upgrading of various industries.