- Introduction to automatic batching machine and fully automatic batching machine equipment

- The powder metering system tells you about the introduction of the mixing and drying machine

- 1000kg vacuum feeding machine

- Fully automatic small material batching system

- Research on Innovation of Automatic Weighing Machine Technology

- Design and operation of automatic batching system using PLC, industrial computer and frequency converter

CENTRAL FEEDING SYSTEM

- Category:Centralized feeding system

- Hits:303次

- Release Date:2025-06-30

- Share:

- Inquiry

- Details

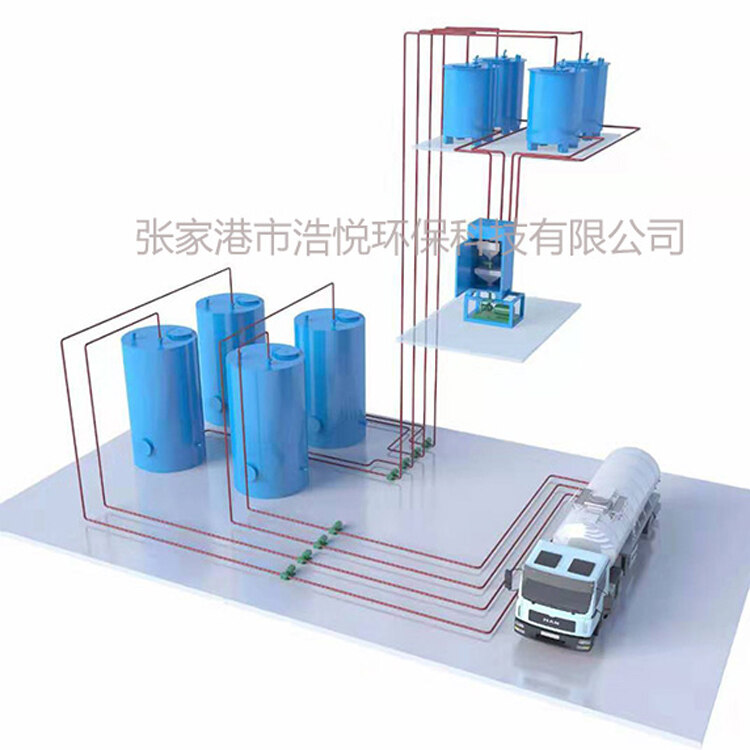

In the process of industrial production moving towards intelligence and automation, the stability and accuracy of material supply have become key factors restricting the production efficiency and product quality of enterprises. The central feeding system centrally manages the storage, measurement, and transportation of various materials, achieving automated material flow from the raw material end to the production equipment, effectively solving the problems of low efficiency and large errors in traditional feeding modes. The following will provide a comprehensive and in-depth introduction to the central feeding system from the aspects of system architecture, working principle, core advantages, application scenarios, and development trends.

1、 System core composition architecture

The central feeding system mainly consists of five modules: material storage unit, precision measuring unit, intelligent conveying unit, central control unit, and auxiliary support unit. Each part works together to form an efficient and stable material supply system.

(1) Material storage unit

The material storage unit is the "material warehouse" of the central feeding system, designed with different storage equipment based on the characteristics of materials (powder, particle, liquid, etc.) and production needs. For granular materials such as plastic pellets and grains, sealed steel silos or plastic storage tanks are commonly used, equipped with level sensors to monitor inventory in real time. When the material falls below the set value, an automatic alarm is triggered to prompt operators to replenish it; Powdered materials such as carbon black and flour are stored in a negative pressure bin with a dust removal device to prevent dust from overflowing; Liquid materials are stored in tanks with temperature control and mixing functions to ensure uniform and stable composition. Each storage bin is independently partitioned to avoid cross contamination, and some systems also support quick switching of storage bins to meet the production needs of multiple varieties.

(2) Precision measurement unit

The precise measurement unit is the core of achieving accurate material proportioning. For different forms of materials, diversified measurement methods are adopted: commonly used for granular materials are weight loss measuring scales and spiral measuring scales. Real time weight changes are monitored through weighing sensors, and combined with the speed control of the spiral feeder, the measurement accuracy can reach ± 0.5%; Powdered materials are measured accurately using volumetric or pneumatic measuring devices by controlling volume or flow rate; Liquid materials can be controlled within ± 0.1% error using mass flow meters and volumetric metering pumps. The measuring unit can automatically adjust parameters according to the production formula to ensure the accuracy and consistency of each feeding.

(3) Intelligent conveying unit

The intelligent conveying unit is responsible for conveying the measured materials to the production equipment. Select different conveying methods based on material characteristics and conveying distance: pneumatic conveying or vacuum feeding system is used for powdered materials, and dust leakage is prevented through closed pipelines; Mechanical conveying equipment such as belt conveyors and chain plate conveyors are used for granular materials; Liquid materials are pumped through corrosion-resistant pipelines and metering pumps. Metal detection and foreign object interception devices are installed during the transportation process to prevent impurities from entering the production process, and the pipeline adopts a quick detachable design for easy cleaning and maintenance. Some systems also have intelligent path planning functions, which can automatically switch to the optimal conveying route according to production needs.

(4) Central control unit

The central control unit is based on PLC (Programmable Logic Controller) or industrial computer, equipped with customized control software and human-machine interface (HMI). The operator inputs the production formula through HMI, including parameters such as material type, ratio, feeding sequence, and time. The system automatically controls the discharge of the storage unit, the start and stop of the metering unit, and the operation of the conveying unit according to the preset program. During operation, real-time collection of sensor data from various links (such as material level, weight, flow rate, etc.) is carried out, and after comparing with the set values, the equipment parameters are automatically adjusted to achieve closed-loop control. In addition, the control system has fault diagnosis, alarm prompts, data recording, and remote monitoring functions, which facilitate production management and equipment maintenance.

(5) Auxiliary support unit

The auxiliary support unit includes dust removal system, automatic cleaning device, drying and dehumidification equipment, and safety protection facilities. The dust removal system is equipped with suction ports at each stage, and efficient dust collectors are used to reduce the concentration of dust in the workshop; The automatic cleaning device regularly cleans the conveying pipeline and measuring equipment to prevent material residue and cross contamination; Drying and dehumidification equipment for pre-treatment of moisture absorbing materials; Safety protection facilities such as emergency stop buttons, overload protection devices, etc., comprehensively ensure the safety of equipment and personnel.

2、 Working principle and process

After the operator inputs the production task in the central control unit, the system first starts the discharge device of the corresponding storage bin according to the production formula, and transports the material to the precise measuring unit. The measuring unit accurately weighs or measures the material according to the preset measurement value, and stops feeding when the set amount is reached. For example, a weightless weighing scale monitors changes in the weight of the silo and controls the screw feeder to stop feeding when the reduced weight reaches the set value.

After completing the measurement, the intelligent conveying unit transports different materials to the target production equipment in the set order and time, such as injection molding machines, extruders, mixers, etc. During the conveying process, the central control unit continuously monitors the data of each link to ensure the accuracy and stability of material conveying. If there is an abnormal situation (such as excessive measurement deviation, conveying blockage, low material level, etc.), the system will immediately issue an alarm signal and automatically take corresponding measures, such as suspending feeding, starting the backup conveying line, or notifying the operator to handle it.

After the production task is completed, the system can start an automatic cleaning program as needed to clean the conveying pipelines and measuring equipment, preparing for the next production. At the same time, the system automatically records the relevant data of this feeding, including raw material usage, feeding time, equipment operating parameters, etc., providing a basis for production management, cost accounting, and quality traceability.

3、 Core technological advantages

(1) High precision and stability

Through advanced measurement technology and intelligent control systems, the central feeding system achieves high-precision proportioning and stable supply of various materials, significantly improving product quality consistency. In the injection molding industry, the use of this system can reduce the defect rate of products by 30% to 50%.

(2) Efficient and automated operation

Replace traditional manual feeding mode, achieve fully automated operation from raw material storage, measurement to transportation, significantly shorten feeding time, and improve production efficiency. The system can seamlessly integrate with production equipment, achieving 24-hour continuous production and effectively reducing labor costs and intensity.

(3) Flexible production adaptability

Support the storage and quick switching of multiple production formulas, adjust production parameters according to order requirements at any time, and meet the production mode of multiple varieties and small batches. At the same time, the system can flexibly adjust the feeding parameters and conveying methods according to the needs of different production equipment, adapting to diverse production scenarios.

(4) Intelligent management and data traceability

Automatically record the entire production process data and generate detailed production reports. Enterprises can optimize feeding processes, predict equipment maintenance cycles, evaluate production costs, and achieve intelligent production management through data analysis. Complete data recording facilitates product quality traceability and enhances the overall management level of the enterprise.

4、 Application scenarios

(1) Plastic processing industry

In plastic molding production such as injection molding, extrusion, blow molding, etc., the central feeding system precisely controls the ratio and transportation of plastic particles, masterbatch, additives and other raw materials to ensure the stable quality of plastic products. It is widely used in the production fields of automotive parts, home appliance shells, packaging products, etc.

(2) Food and beverage industry

In the process of food processing, precise measurement and dust-free transportation of powdered and granular raw materials such as flour, sugar, salt, and additives are achieved to ensure food safety and product quality. It is commonly used in production enterprises such as biscuits, bread, and seasonings.

(3) Chemical industry

In the production of chemical products such as coatings, inks, adhesives, etc., precise proportioning and safe transportation of various raw materials such as resins, solvents, pigments, etc. are carried out to avoid material leakage and cross contamination, improve product performance and production safety.

(4) Other industries

In industries such as electronic manufacturing, pharmaceuticals, and building materials, the central feeding system also plays an important role. For example, the supply of materials such as plastic pellets and solder paste in the electronics industry, the precise measurement and transportation of pharmaceutical raw materials in the pharmaceutical industry, and the centralized supply of raw materials such as cement and sand in the building materials industry.

5、 Development Trends

In the future, the central feeding system will develop towards intelligence, integration, and greening. In terms of intelligence, artificial intelligence and machine learning algorithms are introduced to enable the system to have self-learning and adaptive capabilities, and to automatically optimize feeding parameters based on production data; In terms of integration, it deeply integrates with the enterprise's ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System) to achieve collaborative management of production planning, material inventory, and feeding operations; Greening is reflected in reducing equipment energy consumption, reducing dust emissions, and using environmentally friendly materials. By optimizing system design and operating modes, it promotes sustainable development in the industry. Meanwhile, with the development of industrial Internet of Things technology, the central feeding system will achieve more remote and real-time monitoring and management, further enhancing the production efficiency and competitiveness of enterprises.