- Introduction to automatic batching machine and fully automatic batching machine equipment

- The powder metering system tells you about the introduction of the mixing and drying machine

- 1000kg vacuum feeding machine

- Fully automatic small material batching system

- Research on Innovation of Automatic Weighing Machine Technology

- Design and operation of automatic batching system using PLC, industrial computer and frequency converter

Explosion proof feeder

- Category:Weightlessness scale

- Hits:265次

- Release Date:2025-06-23

- Share:

- Inquiry

- Details

1、 Explosion proof principle and standards

Explosion proof core design

By controlling the ignition sources such as sparks, high temperatures, and static electricity that may be generated during the operation of the equipment, it is possible to prevent it from coming into contact with explosive environments, thereby avoiding the risk of explosion.

Following international/domestic explosion-proof standards, such as China's GB 3836 series, EU ATEX, US NFPA 70, etc., equipment must pass explosion-proof certification (such as Ex explosion-proof mark).

Explosion proof technology type

Explosion proof type (Ex d): The shell can withstand internal explosion pressure and prevent the spread of explosion to the outside, commonly used in core components such as motors and controllers.

Intrinsic safety type (Ex ia/ib): limits the energy of the circuit to ensure that the electrical sparks/thermal effects generated under normal or faulty conditions are not sufficient to ignite explosive gases.

Increased safety type (Ex e): reduces the risk of sparks/overheating during equipment operation through optimized design (such as sealing and heat dissipation), suitable for junction boxes, lighting fixtures, etc.

Positive pressure type (Ex p): Fill the interior of the equipment with inert gas or air to maintain a positive pressure to prevent the intrusion of external explosive gases.

2、 Functional Features

Safety and explosion-proof performance

All electrical components (such as motors, sensors, and control boxes) are explosion-proof, and the wiring is sealed to prevent sparks from leaking out.

Mechanical components such as impellers and screws are made of anti-static materials (such as stainless steel and aluminum alloy surface passivation treatment) to reduce static electricity generated by friction.

Grounding the equipment casing to prevent static electricity accumulation; Some models are equipped with temperature sensors that monitor the operating temperature in real-time and automatically shut down when the threshold is exceeded.

Efficient and stable feeding

Select different structures based on material characteristics (powder, particle, block), such as spiral feeders, vibrating feeders, belt feeders, etc., to ensure uniform and continuous feeding.

The feeding amount can be precisely controlled through frequency conversion speed regulation, adjusting gate opening, and other methods, with an accuracy of ± 1% -3%.

Environmental Protection and Durability

Fully enclosed structure with dust removal interface to reduce dust overflow and prevent external explosive gases from entering the interior of the equipment.

The contact material components are made of wear-resistant and corrosion-resistant materials (such as 304/316L stainless steel), which are suitable for harsh working conditions such as chemical raw materials, flammable and explosive dust.

intelligent control

Integrated PLC control system, supporting remote control and automated linkage, can synchronize start and stop with upstream material silos, downstream reaction vessels and other equipment, achieving intelligent management of production lines.

3、 System composition and types

1. Classified by structure and working principle

Spiral explosion-proof feeder

Composition: Explosion proof motor, spiral shaft, U-shaped groove body, sealed end cover, control box.

Features: By rotating and pushing materials through spiral blades, it is suitable for powdery and granular materials, with good sealing performance, and can be transported horizontally or obliquely. It is commonly used in chemical raw materials, flour and other scenarios.

Vibration explosion-proof feeder

Composition: Explosion proof vibration motor, spring bracket, feeding trough, shock absorber device.

Features: Utilizing the principle of vibration to make the material slide along the groove, the feeding amount can be adjusted, suitable for granular and block materials (such as ore and plastic particles), and not easily blocked.

Explosion proof belt feeder

Composition: Explosion proof drive motor, anti-static belt, idler roller, tensioning device, dust cover.

Features: Conveying materials through belt transmission, suitable for bulk granular materials (such as grain and feed), with large conveying capacity and smooth operation.

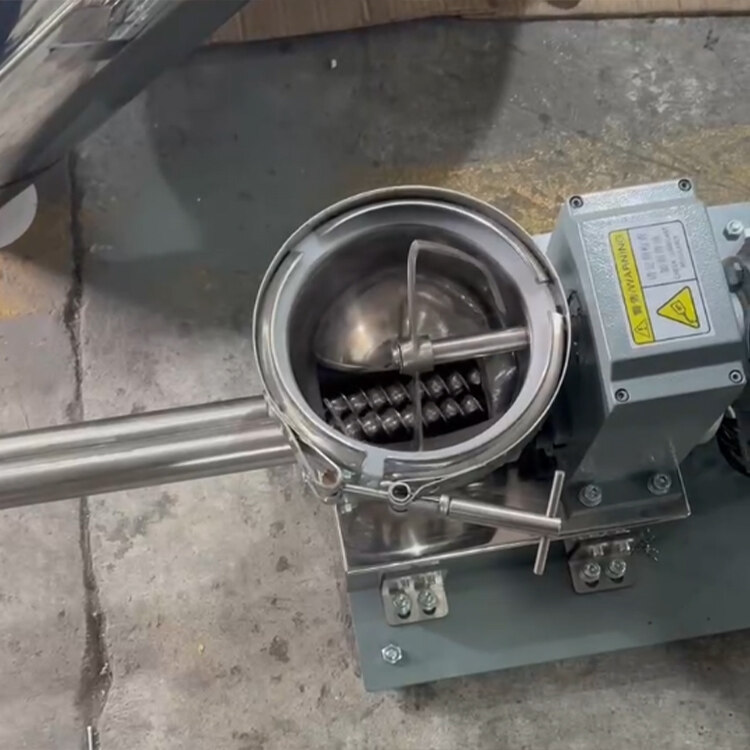

Explosion proof impeller feeder

Composition: Explosion proof motor, rotating impeller, housing, sealing valve.

Features: The impeller rotates to quantitatively discharge materials, suitable for precise measurement of dry powder and granular materials, commonly used in dust explosion prevention scenarios (such as coal powder and carbon black).

2. Core explosion-proof components

Explosion proof motor: It adopts explosion-proof shell and high insulation level of stator winding to prevent spark leakage during motor operation.

Explosion proof control box: Sealed structure, explosion-proof internal electrical components, explosion-proof gland heads at wiring ports to prevent gas/dust intrusion.

Anti static components: Anti static coatings are added to belts, impellers, and other components, or conductive materials are used for grounding to prevent sparks from static friction.

4、 Application scenarios

chemical industry

Transport materials in flammable and explosive gas environments, such as petroleum additives, paint solvents, and particulate materials associated with methane gas, and connect with equipment such as reaction vessels and storage tanks.

Dust explosion prevention scenario

Processing combustible dust such as flour, sugar powder, aluminum powder, and coal powder, commonly used in grain processing workshops, cement grinding stations, and lithium battery negative electrode material production lines.

oil and gas

Transporting solid or liquid materials related to gasoline, diesel, and liquefied petroleum gas (LPG) in oil and gas fields, gas stations, and other places to prevent explosion risks.

Pharmaceutical and Food

Used for handling flammable pharmaceutical intermediates and food additives (such as cocoa powder and sugar powder), meeting both explosion-proof and hygiene standards (such as FDA and GMP).

5、 Selection and safety precautions

Key selection points

Explosion proof level: Select the corresponding explosion-proof level equipment based on the type of explosive substance (gas/dust) and hazardous area (such as Zone 0, Zone 1, Zone 21, Zone 22) on site.

Material characteristics: Considering the fluidity, particle size, humidity, and corrosiveness of the material, choose the appropriate feeder type (such as spiral suitable for dry powder, vibration suitable for particles).

Processing capacity and accuracy: Set the feeding speed and measurement accuracy according to the production line requirements. For continuous production, choose a large conveying capacity machine.

Safety operation standards

The equipment must be grounded, and the integrity of explosion-proof seals should be checked regularly to avoid aging and gas intrusion.

It is prohibited to open the explosion-proof enclosure or disassemble components during operation. Maintenance must be carried out by professionals after power failure and ventilation.

The supporting dust removal system needs to be linked with the feeder to ensure that the dust concentration is below the lower explosive limit (LEL).

The explosion-proof feeder, with professional explosion-proof design and structural optimization, ensures efficient material transportation while ensuring safe production. It is an indispensable automation equipment in flammable and explosive environments. Its application not only reduces the risk of manual operation, but also enhances the intelligence and safety of industrial production.